Description

DTF printing cost is cheaper and printing process is simple than DTG or Sublimtaion.

Direct to film printing is a unique printing technology that involves printing designs onto special films for transfer onto garments. DTF printing is a heat transfer process that has the ability to last as long as traditional silkscreen prints

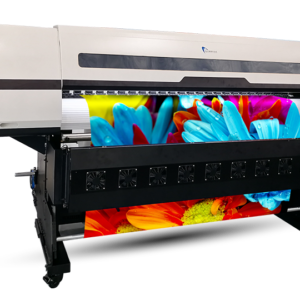

Printhead: 2*EPSON I3200-A1

Printhead Resolution: 3200DPI

Printing Speed: 20sqm/h

Print Width: 600mm

Ink: InkTec dtf Ink

Ink Color: CMYK+W

RIP Software: Maintop,Photoprint

Direct-to-film printing is a unique printing technique that involves printing designs onto special films for transfer to garments. DTF printing is a thermal transfer process with the ability to last as long as traditional screen printing. Below, we’ll discuss five things you should know before implementing DTF technology in your business.

1.Quality equipment is critical If you own a printing business, you already know that the quality of your work is as important as the quality of your printer and ink. Even more so when it comes to DTF printing. As with other heat transfer processes, it’s critical to buy a quality printer and heat press to get the best results. INKTEC provides high-quality and stable DTF printers, if you have a demand, please send us an inquiry in time. High-quality ink is also required to ensure that the printheads do not clog. We recommend inks specially formulated for DTF printing; INKTEC selects inks for better quality assurance due to rigorous testing. It provides results with high color density and saturation, excellent performance and durability.

2.Not all PET films need to be cut PET film is required for DTF printing,but this does not mean that every type of PET film is suitable for the DTF process. For best results, choose the print film that best fits your machine. Lower quality untreated films may be cheaper, but they simply cannot match the performance of INKTEC carefully selected PET films – they may stain, not accept adhesives or ruin your clothes. INKTEC DTF film is specially treated to withstand the high temperature and pressure of heat presses; it is also compatible with all desktop and large format DTF printers. This film can be purchased as a sheet or in rolls for more operations.

3.Choose your adhesive wisely Printing on PET film cannot be transferred directly to garments. Instead, hot melt powder must be used to help the image adhere to the fabric. At www.todojet.com, we offer a unique adhesive for DTF printing that is durable enough to withstand multiple hand washes while keeping the transfer feeling soft. No unpleasant smell, excess can be stored and reused.

4.The fabric does not need to be pretreated One of the many advantages of DTF printing is that garments do not require any pre-processing to accept transfer.This can simplify your operations and potentially reduce your costs.Overall,the DTF printing process is faster than DTG printing,requires less labor, and is more suitable for mass customization.

5. DTF printing offers more possibilities When printing directly to textiles, your options are limited to pure cotton. DTF gives you more flexibility as you can print on a variety of fabrics including cotton,polyester,rayon,nylon,silk,leather and more.