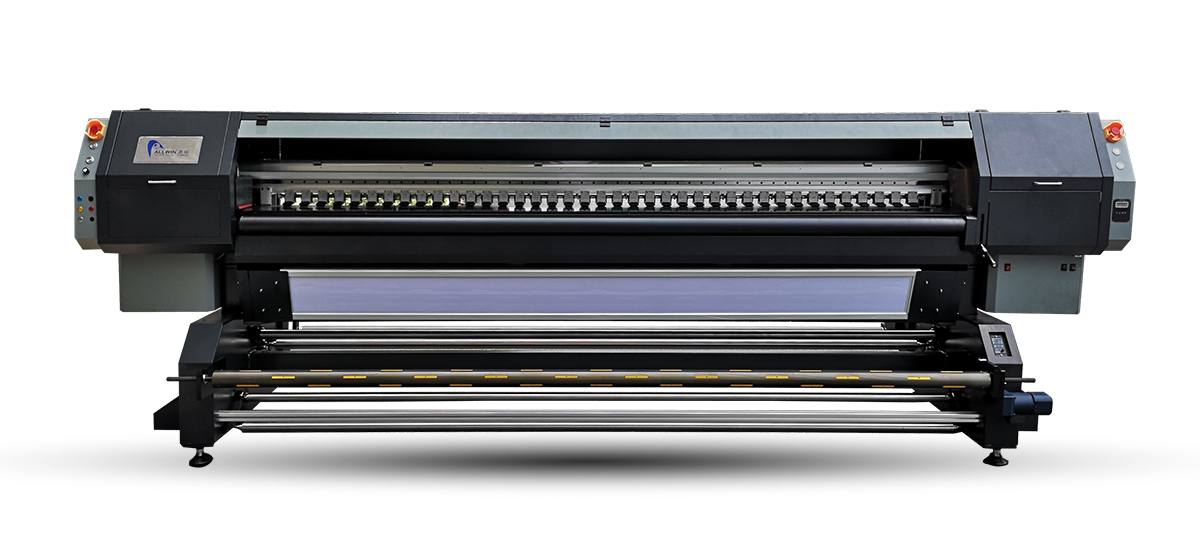

Description

1. Optimized design of the unwinding structure to meet the printing needs of various materials of external light, internal light and soft film;

2. Compared with the four rubber roller machine, the media loading and unloading is convenient and flexible, reducing the operator workload of changing the material frequently, reducing the tailings. Less material scrap, and reduce production costs;

3. The whole machine cost is low, which is convenient for customers to quickly receive various small orders for production;

4. External computer support, saving installation space;

5 .Densely pinch roller arrangement;

6. Cooperate with professional feeding system to ensure the accuracy of stepping.

Additional Information

| Machine Model | 3.2M Pinch roller UV Machine |

| Printhead model | KONICA 1024i,6pl |

| Printhead control | Software adjust printhead temperature and voltage |

| Printhead configuration | CMYK+W/ CMYK+LCLM |

| Maximum printing width | 3.2M |

| Maximum printing Resolution | 2160 DPI |

| Maximum printing Speed | 65m2/h (3 PASS) |

| Ink type | UV ink |

| Color configuration | CMYK+W or CMYK+LCLM (Optional) |

| Ink supply method | Vacuum negative pressure automatic continuous ink supply |

| Drying device | UV LED Curing |

| Package size | 5000mm(L)*1050mm(W)*1630mm(H) |

| Machine size | 4840mm(L)*1320mm(W)*1560mm(H) |

| Machine GW | 1135 KGS |

| Machine Voltage | 220 V |

| RIP software | Print factory/Photoprint/Caldera |

| Speed | Production mode | High-precision mode |

| 3pass | 65m2/h | 36m2/h |

| 4pass | 45m2/h | 28m2/h |

| 6pass | 30m2/h | 15m2/h |